Salt&Iron Food Group, immersed in a splendid journey of elegance for two decades, is a non-family-owned enterprise dedicated to the research, development, production, and sales of frozen semi-finished food ingredients. The group proudly oversees three major manufacturing bases: Jiangsu Yuheng Food Co., Ltd., Jiangsu Salt&Iron Food Technology Co., Ltd., and Jiangsu Shijing Mill Food Co., Ltd., collectively forming the formidable entity known as Jiangsu Salt&Iron Food Group.

Jiangsu Salt&Iron Food Technology Co., Ltd., stands out as a gem within the group. It is a place where the essence of history and culture converges with modern technological achievements. With traditional craftsmanship and cutting-edge technology harmoniously blended, this site spans approximately 100 acres of land, accommodating a magnificent structure of 39,441 square meters. It houses a production line with a daily output of 350 tons, boasting an annual production capacity exceeding one hundred thousand tons and an annual output value reaching six billion yuan. More impressively, the company boasts an experienced research and development team, dedicated to continuous innovation for the delivery of delectable and healthy culinary delights to esteemed customers.

Committed to continuous innovation, providing customers with a variety of delicious and healthy food choices.

Cooperative suppliers include leading domestic enterprises such as Shengnong, Xiantan, Liuhe, directly procuring raw materials with full traceability throughout the entire process.

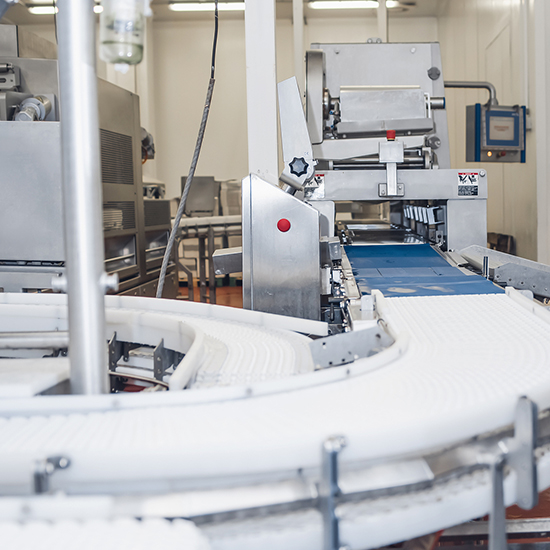

Equipped with automated production lines, a six-stage automatic temperature control thawing system, and real-time alarms to ensure the quality of thawed raw materials. It features a large-scale cold storage with a storage environment of minus 18 degrees Celsius, as well as imported compressors and vacuum kneaders to fully ensure product quality. The multifunctional physical and microbiological testing center acts as a guardian for food safety.

Using automated production lines to reduce manual operations, minimizing food safety risks. Employing an all-weather electronic monitoring system for comprehensive monitoring of the production site around the clock, ensuring the effectiveness of food protection work.

Strictly following domestic and industry standards, and obtaining ISO22000 food safety management system certification and HACCP quality control system certification. The entire process adheres to GMP good operating practices, chemical analysis, and testing methods.

The company has an experienced quality control team, implementing complete control from raw material inspection to finished product shipment.

2-10 year old children's sensory ability training

The spring bamboo Taiwanese Meatballs is a fresh and delicious home dish with the crisp and tender spring bamboo shoots and the fresh fragrance of Taiwanese Meatballs. The common cooking methods are steamed, braised in soy sauce and boiled in soup. The operation is simple and the flavor is different. The specific steps are as follows:

2026-01-20

The key to making pork chops with bones lies in the tenderization of the meat, uniform flavor, control of the frying and baking heat, while also taking into account the taste and complete shape of the bone border meat. Specific precautions are as follows:

2026-01-13

Fresh meat rolls (such as pork rolls, beef rolls, and lamb rolls) are tender and easy to cook. The core idea of their combination revolves around "soup base/cooking method + side dishes + dipping sauce". They are suitable for various eating methods such as hot pot, stir-frying, boiling, and cold mixing, balancing both taste layers and nutritional balance.

2026-01-05

The core cooking method for black pepper meatballs is mainly fast frying, which is suitable for different ingredients and taste requirements. It has also evolved into methods such as pan frying, jelly frying, deep frying, and stir frying. The ingredients are mostly beef tenderloin and pork tenderloin, and low-fat versions can also be made with chicken breast. Below is a detailed breakdown of mains

2025-12-30

The commercial operation of boneless chicken fillet can be implemented in five steps: "model selection - product and supply chain - store operation - marketing and customer acquisition - digitalization and compliance", covering small-scale entrepreneurship to chain expansion, balancing low cost and high return. The following is a complete plan that can be directly executed:

2025-12-23

The reason why farm stir fried meat is recommended for people with poor appetite is mainly due to its rich flavor, suitable taste, and appetizing combination of ingredients. It can promote appetite from taste, smell, and texture, while also considering digestive friendliness. The specific reasons are as follows:

2025-12-16

The spring bamboo Taiwanese Meatballs is a fresh and delicious home dish with the crisp and tender spring bamboo shoots and the fresh fragrance of Taiwanese Meatballs. The common cooking methods are steamed, braised in soy sauce and boiled in soup. The operation is simple and the flavor is different. The specific steps are as follows:

2026-01-20

The key to making pork chops with bones lies in the tenderization of the meat, uniform flavor, control of the frying and baking heat, while also taking into account the taste and complete shape of the bone border meat. Specific precautions are as follows:

2026-01-13

Fresh meat rolls (such as pork rolls, beef rolls, and lamb rolls) are tender and easy to cook. The core idea of their combination revolves around "soup base/cooking method + side dishes + dipping sauce". They are suitable for various eating methods such as hot pot, stir-frying, boiling, and cold mixing, balancing both taste layers and nutritional balance.

2026-01-05

The core cooking method for black pepper meatballs is mainly fast frying, which is suitable for different ingredients and taste requirements. It has also evolved into methods such as pan frying, jelly frying, deep frying, and stir frying. The ingredients are mostly beef tenderloin and pork tenderloin, and low-fat versions can also be made with chicken breast. Below is a detailed breakdown of mains

2025-12-30

The commercial operation of boneless chicken fillet can be implemented in five steps: "model selection - product and supply chain - store operation - marketing and customer acquisition - digitalization and compliance", covering small-scale entrepreneurship to chain expansion, balancing low cost and high return. The following is a complete plan that can be directly executed:

2025-12-23

The reason why farm stir fried meat is recommended for people with poor appetite is mainly due to its rich flavor, suitable taste, and appetizing combination of ingredients. It can promote appetite from taste, smell, and texture, while also considering digestive friendliness. The specific reasons are as follows:

2025-12-16